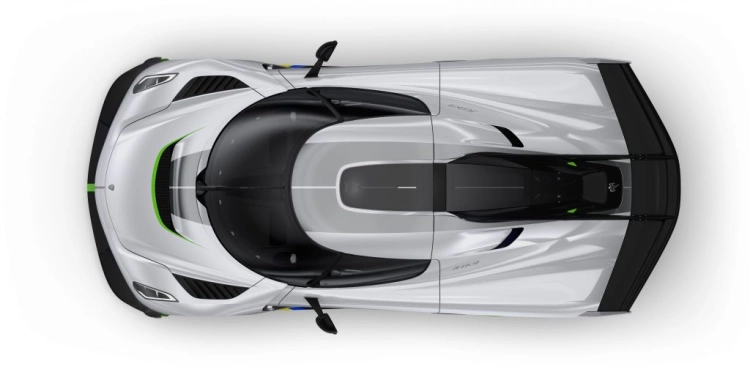

Koenigsegg Jesko

The Koenigsegg Jesko inherits the mantle left by the Agera RS as the leading track-focused, road-legal car for those looking for the ultimate in vehicle performance.

The Name

Jesko is named for Jesko von Koenigsegg, the father of company Founder and CEO, Christian von Koenigsegg. Jesko von Koenigsegg was a key presence at Koenigsegg Automotive during its formative years. His considerable business acumen helped steer the company through many early challenges.

The Car and its Engine

The next Koenigsegg engine achieved a similar feat when the CCR took the world production car top speed record, again from the McLaren F1. In 2014, we announced the Koenigsegg One:1 with a twin-turbo V8 producing 1,360 hp, enough to make the One:1 the first production car in history with a 1:1 power-to-weight ratio. With 1 megawatt of power, the One:1 was the world’s first Megacar.

Jesko - the all-new mega car from Koenigsegg - is powered by a newly designed, 1280hp (1600hp on E85), twin-turbocharged V8 engine that benefits from significant changes to the Agera engine it replaces.

At the core of the newly designed engine is the world’s lightest V8 crankshaft. Weighing just 12.5 kilos, Koenigsegg’s new flat-plane 180-degree crankshaft allows Jesko to produce more power, with greater efficiency, while achieving a higher 8500rpm rev limit.

The crankshaft is milled by a small manufacturing house located in southern Sweden. It is made to Koenigsegg’s in-house design from a single solid steel billet.

The flat-plane design allows even firing across engine banks and an even more visceral engine sound. Koenigsegg has countered the tendency that flat-plane engines have towards greater vibration by designing new super-light connecting rods and pistons.

The connecting rods were designed by Koenigsegg’s engine architect, Dr. Thomas Johansson. The connecting rods are made from premium Swedish steel. At just 540g - including bolts - they’re as light as previous generations made from titanium but even stronger.

The piston’s curved face shapes the combustion chamber in such a way so as to reduce peak pressure while maintaining high average pressure. The ceramic coating on the face of the piston prevents hot spots and detonation when the engine runs at maximum power. The piston weighs just 290 grams. Minimal weight is important because Koenigsegg engines have a very long stroke and at 8500rpm, the efficiency of movement becomes critical.

The Koenigsegg Jesko features an all-new 9-speed, multi-clutch transmission - the second transmission to be 100% designed and built in-house at Koenigsegg, following the Direct Drive system designed for the Regera.

The Koenigsegg Light Speed Transmission (LST) represents a scale of evolution not seen since the development of modern dual-clutch technology at the turn of the century.

LST comprises nine forward gears and several wet, multidisc clutches in a compact, ultra-light package. The LST is capable of upward and downward gear changes between gears at near light speed thanks to the simultaneous opening and closing of clutches that allow for totally seamless acceleration/deceleration.

That LST gear changes can occur in virtually zero time between adjacent gears is impressive. What takes LST from impressive to evolutionary, however, is that these shift-time benefits apply when changing between ANY forward gears.

Interior and Equipment

The new Koenigsegg Jesko is unapologetically designed to be the most capable track-oriented car ever made for the road. It is engineered for prodigious speed - both straight-line and lateral - with total driver control. That doesn’t mean one has to be uncomfortable, however.

Jesko is equipped with a full suite of creature comforts and a level of convenience more befitting a grand tourer than your typical track weapon.

The simple push of a button on the elegant Koenigsegg remote control operates Autoskin, the pioneering body opening system first shown on the Regera. Miniaturised hydraulics that was initially designed to operate aerodynamic systems now engage to open the car’s doors and hoods, allowing true touchless entry.

Koenigsegg’s signature dihedral synchro-helix door hinge has also been re-designed. It now opens slightly outwards and upwards compared to the original. This provides even more room for ingress and egress and reduces the danger of scraping high curbs. The Autoskin system includes sensors to protect both automated doors from the opening where an obstruction is detected.

The interior is swathed in luxury materials - leather, Alcantara, carbon fiber, aluminum, and glass.

Find more Cars

Aston Martin DB12 Goldfinger Edition

Aston Martin DB12 Goldfinger Edition celebrates the 60-year partnership of ...

The Porsche Panamera range is growing

With the addition of the new 330 hp versions and the Executive models, the ...

The new Bentley Continental GT V8 S model

The appeal of the world's most stylish, luxury grand tourer is enhanced wit...

Highlights from Geneva 2013

Lamborghini, Ferrari, McLaren, Koenigsegg, and Spyker among the favorites a...

The Aston Martin Valour

The Aston Martin Valour celebrates the brand's 110th anniversary by honorin...

Bentley Flying Spur Hybrid

The new Bentley Flying Spur Hybrid is the next step to achieve an end-to-en...